How to Make Your Ratchet Straps Last Longer

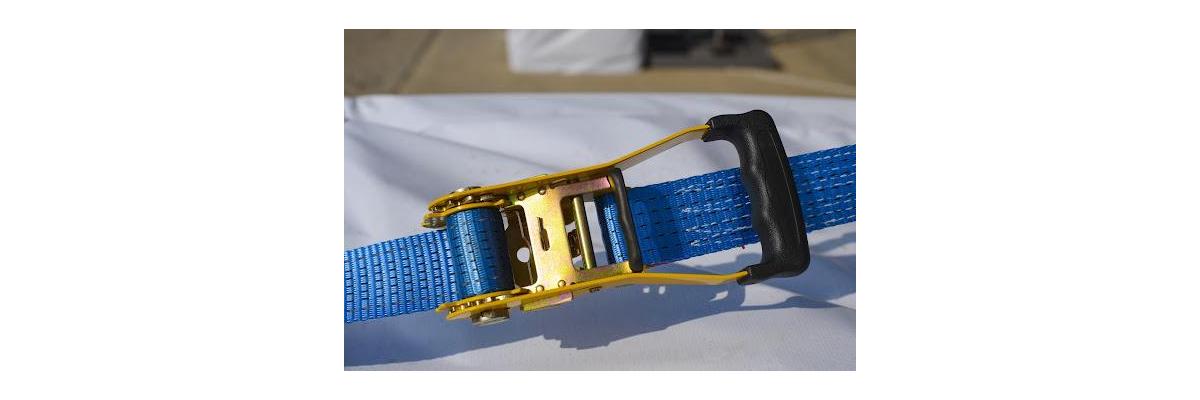

If you regularly transport goods, you’ll know that ratchet straps, or ‘tie-downs’, are one of the most important pieces of kit that money can buy.

Be it for long-distance cargo transportation or for securing furniture when moving house, ratchet straps prove to be an essential tool time and time again. In fact, ratchet straps make fastening and securing loads such a breeze that we couldn’t imagine life without them.

Shockingly, though, not everyone takes care of their tie-downs despite knowing how crucial they are for health and safety measures in the transportation of large goods.

In this blog post, we’ll run through some of our tie-down ‘best practices’ that’ll keep your tying down tools in top condition for as long as possible.

Read on to learn how to take care of your ratchet straps so that they can take care of your cargo for longer. Or, learn how to use a ratchet strap by watching our simple video in the meantime.

1. Keep Your Ratchets Oiled Up

To keep your ratchets operating smoothly for years on end, we recommend lubricating them with a spray or industrial oil.

Regular lubrication of your ratchets will prevent snagging and pulling from occurring during use which could cause rip damage. For the best results, stay clear of lubricants such as WD-40 as they dry up pretty quickly. Instead, use more long-lasting lubricants. Take care, though, to only apply the lubricant to the ratchet and not the strap or webbing as repeated exposure may cause the webbing to corrode over time, reducing effectiveness.

2. Don’t leave ratchet straps in the sun

All of our ratchet straps — heavy-duty and lightweight — are made from 100% polyester. While this material is incredibly strong and withstands repeated rigorous use, it doesn’t fare so well in the sun.

UV rays from the sun can break down polyester fibres over long periods of time, causing ratchet straps to become brittle and discoloured.

Brittle, inflexible straps make fastening jobs increasingly difficult and can snap if left for extended periods of time. When your ratchet straps aren’t in use, store them in a shaded place such as a garage or toolbox to avoid sun damage and keep them stronger for longer.

For safety purposes, we recommend examining the colour of each ratchet strap regularly as discolouration is often the first sign of sun damage and weakening.

Head over to our blog for more advice on how to store your ratchet straps.

3. Dry your ratchet straps before storing them

While it is tempting to just roll up your ratchet straps and forget about them after a long, wet day of transporting loads, this is one of the worst habits to get into when it comes to using ratchet straps.

Putting away tie-downs when they are still wet encourages the rapid growth of mould and mildew spores which, like exposure to the sun, can weaken the strength of even strong ratchet straps over time. Just as you would a tarpaulin, or even laundry, wait for your tie-down to dry out between uses — unless it’s an emergency.

4. Remove webbing from the ratchet

When not in use, it is important to dismantle your ratchet straps, keeping the webbing and metal ratchet separate from one another.

Leaving the webbing inside the metal ratchet (or handle) may lead to it getting wound too tightly or weakening in one particular area. Although it may elongate the fastening process next time, this small tip is sure to extend the lifespan of your ratchet straps if adhered to.

5. Wrap webbing around the ratchet

Instead of leaving your tie-downs to tangle up and become a tripping hazard, secure your webbing around its ratchet.

A great way to prevent your workspace or vehicle from becoming cluttered is to wind the webbing around the metal handle right up to the ratchet strap ends and secure it with a rubber band. Not only does this keep things tidy, but it protects the metal ratchet from road vibration damage too. Check out our blog post on how to store your ratchet straps for a detailed overview of coiling traps.

6. Keep straps away from heat and friction

Many hauliers get into the bad habit of leaving their tie-downs to hang loose when not in use.

Leaving straps to flap about is dangerous not only because it could damage the vehicle or other vehicles nearby, but the strap could rub and weaken over time. Do your best to keep your tie-downs away from moving parts and direct heat sources to avoid burning or severing — especially mini ratchet straps that are more delicate.

If you do, however, notice a lesion or burn mark on your tie-downs, a replacement should be bought immediately. For extra protection against abrasion damage, invest in a wear sleeve for your ratchet straps.

7. Inspect your straps regularly

Before every use, take a few seconds to inspect your tie-downs for any signs of wear and tear or serious damage. Injury or damage as a result of using ratchet straps improperly has legal consequences, so it is important to double check.

As stated above, discolouration is the first sign of a strap weakening, while burn marks, tears, and rips are always a cause for concern and should stop a strap from being used. Also, keep an eye out for any missing identification labels as these inform users of the maximum weight each strap can take. Keep yourself and others safe on the road and take care of your ratchet straps well to keep them usable for longer.

For more advice on caring for your ratchet straps, get in touch with our experts, visit our blog, or browse our full range of ratchet straps and vehicle recovery sets on our website.